The twin turbo Mazda Rx7 put the world on notice when launched back in 1993. Sexy and capable, I was lucky to be able to drive the first one in the state as knowing the right people does come in handy.

The twin turbo Mazda Rx7 put the world on notice when launched back in 1993. Sexy and capable, I was lucky to be able to drive the first one in the state as knowing the right people does come in handy.Now in its later years the reality is that these cars need TLC, we have had many come in for basic maintenance (including a compression test for understanding the inner workings). I have had only one that failed that test in the last year and that car needs a rebuild and is on the schedule for this winter.

- What are the top priorities during disassembly when rebuilding that motor?

First is going to be all the components underneath the intake manifold relating to emissions. There are 64 vacuum hoses, that is a lot to get replaced and right, make sure to use silicone replacement hose so it can handle the heat cycles. Now, many of you think why not eliminate all that emission stuff, well the EPA has something to say about that. And, it isn't good for professional shops or the owners of this FD. For a dedicated track car, this would a different type of build. We have seen shops get fined for removing emissions on street going vehicles, it is not worth it, and to think that a highly modified vehicle is going to pass emissions is a risk for others to take.

First is going to be all the components underneath the intake manifold relating to emissions. There are 64 vacuum hoses, that is a lot to get replaced and right, make sure to use silicone replacement hose so it can handle the heat cycles. Now, many of you think why not eliminate all that emission stuff, well the EPA has something to say about that. And, it isn't good for professional shops or the owners of this FD. For a dedicated track car, this would a different type of build. We have seen shops get fined for removing emissions on street going vehicles, it is not worth it, and to think that a highly modified vehicle is going to pass emissions is a risk for others to take.With the OBD1 set up, having the right testing equipment to read codes is not an option when it comes to properly understanding what is going on. I have had owners not even know this is an option (and want to argue about it). It is there, and the right equipment helps when diagnosing issues. It is good to get codes before pulling the engine.

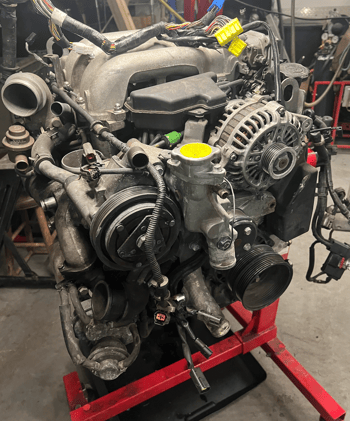

Next is to take your time removing the turbos and checking every connector (electrical and mechanical) for proper understanding of operation. This is a technical masterpiece from an era gone by. Take notes and look for gasket leakage, broken heat shields and the oil / water connectors. Next is the turbo itself, for most the turbos will be worn beyond their useful life as the bearings and seals are going to need to be replaced. The easy check it to check the end play on the turbo shaft.

For this build, we chose to go the route of a new turbo, the factory JDM 280 PS version as the new factory for the US market is no longer available for the FD's. Excellent choice by the owner. Up next is everything that surrounds the engine block.

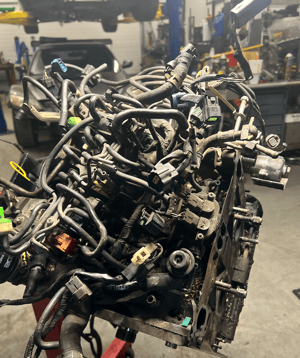

For this build, we chose to go the route of a new turbo, the factory JDM 280 PS version as the new factory for the US market is no longer available for the FD's. Excellent choice by the owner. Up next is everything that surrounds the engine block.After the components are removed from the block, and pictures of where things go (remember there are a lot of hoses and connectors on top of this engine, make sure that you identify where hoses (there are 64 old and tired vacuum hoses) and the wiring harness go because if you twist one part of the harness that will shorten it and make connections hard to make on reassembly.

We look at every connector and replace connectors that break (primarily the locking clips are the ones that break) and make a list during disassembly.

Now that the engine is on the engine stand and the stack is ready, removing the long tension bolts is next (after the flywheel components). How the tension bolts are removed matters, feel the way they turn will indicate the tension loads that have taken place. Most will just use the impact wrench and remove all of them, experience comes into play, details matter.

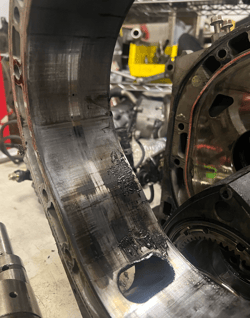

Now that the engine is on the engine stand and the stack is ready, removing the long tension bolts is next (after the flywheel components). How the tension bolts are removed matters, feel the way they turn will indicate the tension loads that have taken place. Most will just use the impact wrench and remove all of them, experience comes into play, details matter.Once you get the rear plate off and start removing the rotors, you can see a lot of what happened that led to the motor failing and just as important, if the wear will mean replacing more than just seals and springs.

We document, take a lot of pictures and then head to the ultrasonic cleaner to get all components clean so we can start the inspection / measurement procedures.

Topics: mazda rx7, Rotary Engine REbuild, 13b