Mazda Engine Rebuilds | Before it blows up

Rotary Engine Compression Testing | I’ll deal with it when it gets worse, ….

REady for a Turbo?

…..so many budget-minded people do not want to spend money unless it is critical, wait, aren’t we all like that?

The facts are clear to those who have taken apart 100’s of rotaries, internal components not where they should be will destroy a motor, even faster with a rotary engine.

All racing motors get a compression test | Why get a compression test when it runs right now?

Motors that are built properly will slowly degrade with use (and a motor that is sitting isn’t going to fair well either).

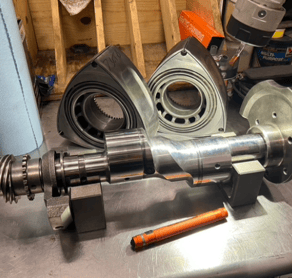

The compression test will show you how the motor is working internally, and save a lot of money. The main parts of the rotary engine are the rotors themselves, they can handle high loads and heat, what they cannot handle is bad rotor bearings, what happens is that the rotor (while spinning) will hit the side housing, and that starts a chain reaction. Slamming side to side will scuff the side housing, break side seals…..the result is parts being tossed around tearing up everything in its path.

Rotary Engine Rebuilds | How do we get away from this action?

Let’s go over several details on what makes a good rotary engine build:

First the build must be for the intended application. If your are racing (and why not with a rotary), pulling redline with most shifts, the rotors like to have a couple of thousands taken off each side. This has proven to be a very good thing for race motors.

Second, using proper tolerances for side seal grooves and end gap with the corner seals. Every motor built is prepped by individually grinding each and every side seal for proper clearance. Too much and down goes compression, too little and it sticks when it gets hot.

Third, we carefully measure the apex seal groove. Not only for the fit, but for the groove to be parallel and specific for the apex seals themselves. Get it wrong and the potential for breaking an apex seal goes up.

Third, we carefully measure the apex seal groove. Not only for the fit, but for the groove to be parallel and specific for the apex seals themselves. Get it wrong and the potential for breaking an apex seal goes up.

The list goes on, every race motor gets a racing oil pressure relief valve. You can take (some years) the stock one and crush it in a vice for increased pressure, however how will you know what it is supposed to hold pressure at? Don’t take that chance.

Details in prepping a motor for the rebuild takes most of the time, this is not the place for taking any shortcuts, or ‘close enough’ thinking. Since I’ve started building them (1988), a lot of people have jumped on the bandwagon, I have some excellent relationships with the fastest racers, our communications over the years and spending time at the track and on the dyno keeps the mind fresh and the process up to date.

Get the horsepower you crave along with the reliability of a solid build. Quality matters.

Topics: engine builds, rotary engine care