Exploring the realm of social media platforms, one can easily spot discussions and articles on achieving substantial power gains with the 13B rotary engine.

Exploring the realm of social media platforms, one can easily spot discussions and articles on achieving substantial power gains with the 13B rotary engine.

Easy, right? Not so fast.

Every online provider of content wants you to know how easy it is because anyone can do it ...with a large enough budget.

For some it is to go larger turbo, for others it is the fine balance of handling & power of the NA.

As a race car driver & builder, I prefer the latter. Why? Because of personal preference, I don't need 5-700 horsepower, all that means is I break a lot more parts to keep up with the other 600+ hp competitors. Road racers are a unique breed, straights are for the car, corners are for the driver.

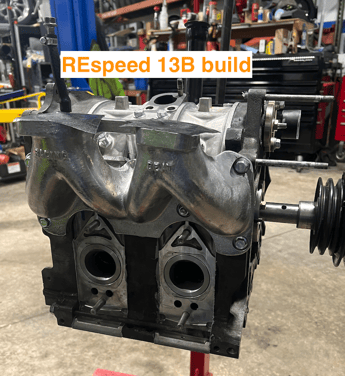

Building the NA 13B for time attack / time trials SCCA | Let's take a deeper look at one of our builds:

The hard truths about making solid power gains starts with the internals. For turning multiple laps at speed, pushing G forces and wearing out tires, the rotary engine internals need some additional help with bearings, oil flow and of course side seal clearances.  The larger competition rotor bearings are a good start, they don't like idling or driving around town much, but holding high rpm's and keeping things within the heat range (185-195 degrees) works well for track time. Remember these motors push a lot of volume through the center to pull heat out of the rotors, keep them in the right temp range and the power and longevity live on.

The larger competition rotor bearings are a good start, they don't like idling or driving around town much, but holding high rpm's and keeping things within the heat range (185-195 degrees) works well for track time. Remember these motors push a lot of volume through the center to pull heat out of the rotors, keep them in the right temp range and the power and longevity live on.

Next up is having a matched set of rotors, after we ultrasonic clean them, we measure up every square mm. and weigh them for comparison. Depending on budget and how they turn out, we will send them off to be balanced with the e-shaft and counterweights. Rotating mass is everything here. Do it right, build it to last.

- The meticulous attention to every detail culminates in enhanced performance and long-lasting durability.

After we get the balanced rotating assembly back, it is time to start setting up the rotors, press in new bearings, new oil control rings / o-rings, side seals / springs. This is where the true engine building comes or it doesn't. Grinding side seals for clearance is an art. Having built a lot of motors over the years, I appreciate the advancement of precision grinding wheels to allow us to keep our specs consistent for every engine we build. Rotor housings and Apex seals: On builds that are pushing power, there is very little reason to use worn rotor housings. That contact of the apex seal and the rotor housing is critical. Do it right, do it once. Choice of apex seals comes down to preference and past experience. If you have one preferred choice, be able to back it up with reasons why. We share our experience on every build and why. Our experience comes from years of racing and our groups of other engine builders & racers.

Rotor housings and Apex seals: On builds that are pushing power, there is very little reason to use worn rotor housings. That contact of the apex seal and the rotor housing is critical. Do it right, do it once. Choice of apex seals comes down to preference and past experience. If you have one preferred choice, be able to back it up with reasons why. We share our experience on every build and why. Our experience comes from years of racing and our groups of other engine builders & racers.

- Finally, we arrive at the crucial stage of assembling the 13B rotary engine.

On assembly, there are a lot of different opinions and some well kept secrets. Assemble the rotors & e-shaft ahead of time. All porting is to be done days in advance with multiple checks for consistency and port volume that matches the application. On these older side housings, the castings are critical, miss something and they may not hold the large O-rings properly in place when you stack the motor. This is where experience matters.

The motor is now together, time for the oil pump, front bearings, thrust washer and spacer. End play and why this matters. This is very important for motors that will see high rpm's and sustained loads need to have the proper end play. The engine will expand with the heat, that plays hell with the thrust washers & needle bearings, once it tears that up, the main bearings are next and then the rotors start rocking, tearing the engine up.

Get the end play right, adding clearance over OEM specs is critical. Details matter.

Topics: Colorado Rotary Engine shop, 13b