The Rotary engine continues to be a solid performer when built properly. Assembling the motor is only one key factor of a good build. The details necessary involve more than just the individual components.

The Rotary engine continues to be a solid performer when built properly. Assembling the motor is only one key factor of a good build. The details necessary involve more than just the individual components.

Every build we do is properly disassembled with a high focus on how it comes apart. The number of heat cycles and prolonged high running temperatures means that the aluminum, cast iron and DIN 9 (and above) bolts all have been stressed, the key is to know / understand when they are past their useful life.

Now, front cover bolts are going to be a lot different than the long through bolts, a stretched long through bolt isn't going to perform as well as a new one. Careful ultrasonic cleaning and measuring / comparing to new will show you just as much as how the bolts loosen when removing them. Overheated components will show themselves if you know where to look.

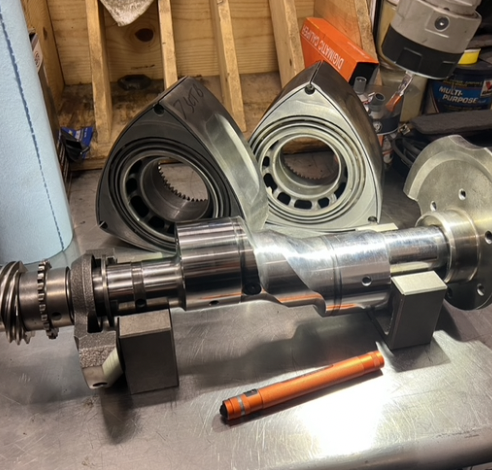

History has shown that when the through bolts are difficult to remove, they have been overheated and possibly stretched. Those several minutes are critical for understanding the current condition of the motor. That helps us develop a specific rebuild plan. From there we get to the plates, rotors & housing removal, then watching how the oil control rings and seals / springs come out. A properly running motor will be different than one that has overheated many times. On motors that ran very hot, expect the oil control rings & side seals to just fall out, the apex seals to be chipped and the springs to be flat.

From there we get to the plates, rotors & housing removal, then watching how the oil control rings and seals / springs come out. A properly running motor will be different than one that has overheated many times. On motors that ran very hot, expect the oil control rings & side seals to just fall out, the apex seals to be chipped and the springs to be flat.

From there, the whole motor is not junk, it needs to be ultrasonically cleaned and measured up. The brunt of many rebuilds for the Rx8 will involve new rotor housings, seals, springs, gaskets and oil control rings. If caught early enough, the side housings will be reusable.

For rebuilding these motors, more time is spent on cleaning and measuring (than most motor builds) to make sure that we get the parts past their life replaced and re-use the good components. The side housings and rotors are pretty tough and can handle a lot. Using the MITUTOYO Digital Indicator (0 in to 0.5 in Range, IP42, ±0.0001 in Accuracy) ensures that we get the best information on condition possible.

Rebuilding / Assembly of the rotary isn't difficult, what is that hard part? Getting the details correct. Consistent side seal clearances, the many little aspects that come from years of experience to know when to discard a component vs. putting it back in service and hoping it will last. Seals are fickle and require time and patience to install correctly. The other issue is removing all of the carbon build up without damaging the rotor surfaces (they are coated).

Check out our many other blog posts and photos, they tell good stories.

Rotary Engine build Blog

Building the Rotary Engine is all in the right tools, experience and knowhow. Get it right

Colorado Rotary Engine shop, engine rebuilds

|

5 Min Read

Rotary Engine REbuilds | details for a solid build

Related Articles

The rotary engine has changed the porting over the years, improving performance and reducing emissions. Intake porting: This is where a lot of gains can be made, on the other side, also a lot of ...

Rotary Engine Shop | Filling out one of our forms connects you to our team and starts a conversation about your Rx. We received a form regarding a rare GSL-SE that requires some TLC and an engine ...

We have had this customer for several years and what amazes me is that the majority do not understand the complexities of our hot dry high altitude. Oh, they talk about it and smooth right over the ...